VSC Air Handler Unit Vibration Case Study

VSC received a semi-annual vibration analysis survey remotely from a client’ Air Handler Unit. The data indicated a problem on the machine that is becoming all too common.

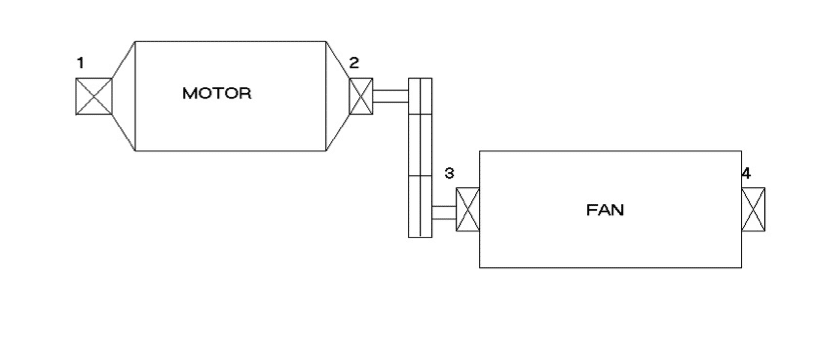

Figure 1: Air Handler Unit Diagram

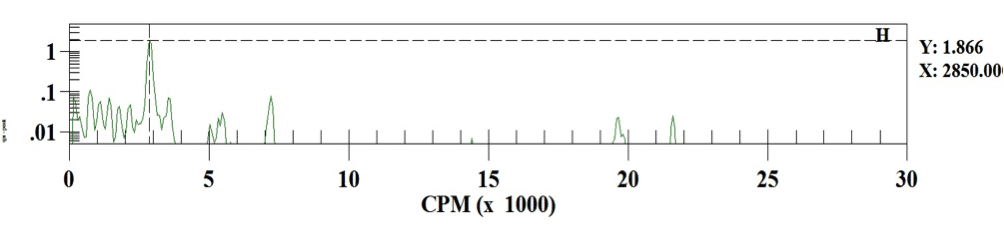

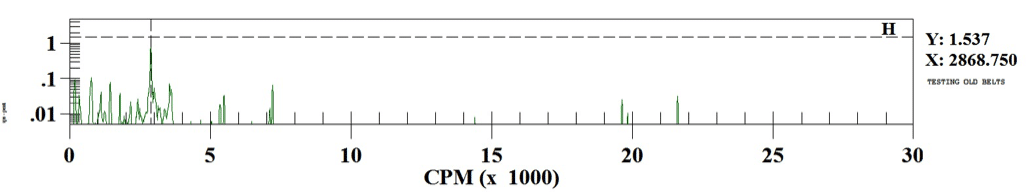

The spectra in figure 2 show peak vibration levels of 1.87 and 1.54 inches per second (ips) at 2850 cycles per minute (cpm). Our engineers reviewed this data and quickly realized that this peak did not match either the motor or fan operating speed harmonics. Further ata review identified the belt frequency of 950 cpm. This made the 2850 cpm peak the third harmonic of the belt frequency, indicating a belt issue.

Figure 2: Air Handler Unit vibration spectra with old belts

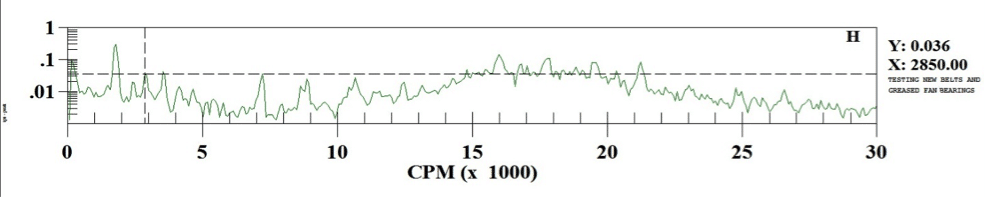

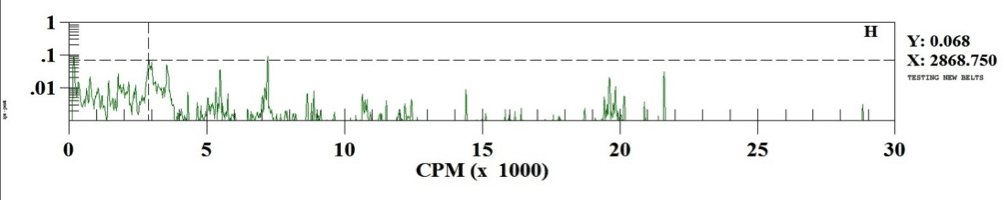

Our personnel notified the client that they needed to inspect their sheaves and belts and to replace them as necessary. The client let us know that they rarely check this machine and the belts and sheaves were in desperate need of changing, which they did immediately. The spectra in figure 3 show the dramatic difference. After peak levels of 1.87 ips prior to belt repairs and bearing greasing, the vibration at 2850 cpm, 3X belt frequency, dropped to 0.07 ips.

Figure 3: Air Handler Unit vibration spectra with new belts

Periodically monitoring the vibration of machinery is the simplest way to get total control of your maintenance program. There is no reason to run your machinery to failure when you can very easily monitor it for early identification of machinery faults. That way you can make simple repairs well before the flaw can escalate and jump off the rails.